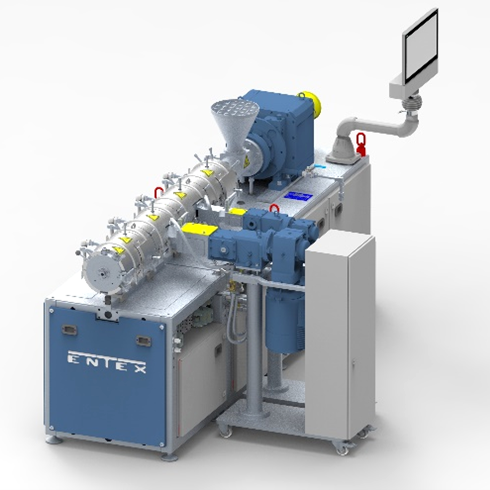

Planetary Roller Extruder / Compounder / Mixer

Product

Information

The ENTEX planetary roller extruder (PRE) allows the compounding of very different materials. A large number of different system components form a modular system from which tailor-made processing systems can be built depending on the specific process requirements.

Today, the PRE is no longer just the classic preparation unit for the PVC industry, but covers the entire range of preparation and process technology. Due to its versatile, individually configurable process zones and effective tempering and degassing, the PRE is also increasingly used in reaction technology.

Fields of application:

- Preparation and compounding processes

- Chemical reaction processes

- High temperature processes

- Recycling processes

- Food processes

- Mixing and dispersing processes

- Degassing processes

- Drying processes

- Cooling processes

The application possibilities of the PRE system are extremely variable due to the many mechanical and thermal configuration options and have already been established for various industrial applications:

- Plastic and Rubber Industries

e.g. all PVC formulations, ABS, TPO, TPU, TPE, filled polyolefins, prepregs, rubber processing, elastomer adhesives, hot melt

- Paint industry

e.g. for epoxy, polyester, acrylic and similar coatings

- Chemical industry

e.g. for compounds with endothermic and exothermic reactions, cooling of compounds, drying of liquids, extraction of condensates and solvents

- Food industry

e.g. for all thermally sensitive recipes, cocoa-sugar dispersions, ice cream, special malts, emulsification processes, vegan formulations

- Pharmaceutical industry

e.g. for granulation of hydrophobic and lipophilic active ingredients, mixing sensitive materials

- Recycling industry

e.g. foil edge trim, devulcanization of scrap tire granulate

- Special applications

e.g. for sewage sludge processing, Wood Plastic Composites (WPC)